Regardless of one’s skill level, failure will occur in the manufacture of chipped stone artifacts, especially at any stage in the linear reduction of bifaces. The most

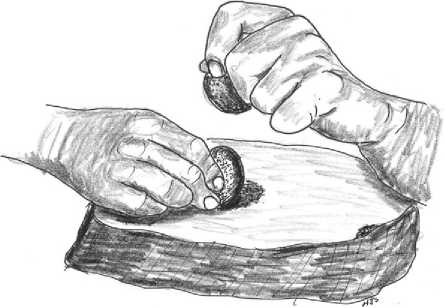

Figure 4 Bipolar reduction method.

Common failure problem is end shock which is a snap fracture caused by vibrations set up when a blow is struck near one end of the piece. The vibrations cause the core to bend, exceeding its elastic limits. Another problem is platform collapse or crushing caused by improperly preparing or strengthening the striking platform. Improper platform preparation may also cause the flake to snap before termination causing a step fracture to occur. Yet another example of failure is a premature termination of the flake as the fracture rolls out to the surface, causing a hinge fracture to occur. Overshot flakes are caused by the opposite of the hinge flake in that the flake terminates hinging downward cutting the core in two. Any of these failures can occur at any step along the way. That is why archaeologists pay attention to the failures and related debitage because these artifacts clearly document the trajectory of manufacture, the intent of the flintknapper with regards to the style of being made, how the manufacturing process was achieved, which tools were used, and even the level of skill employed.

World History

World History