If a stave is about two inches thick, it should be steamed or boiled at least an hour before bending. If bending a limb tip into a sharp recurve, it is also safest to boil or steam the wood for at least an hour, to prevent fractures. If the wood is an inch thick or less and is to be bent only slightly, it can be steamed or boiled for 30 minutes.

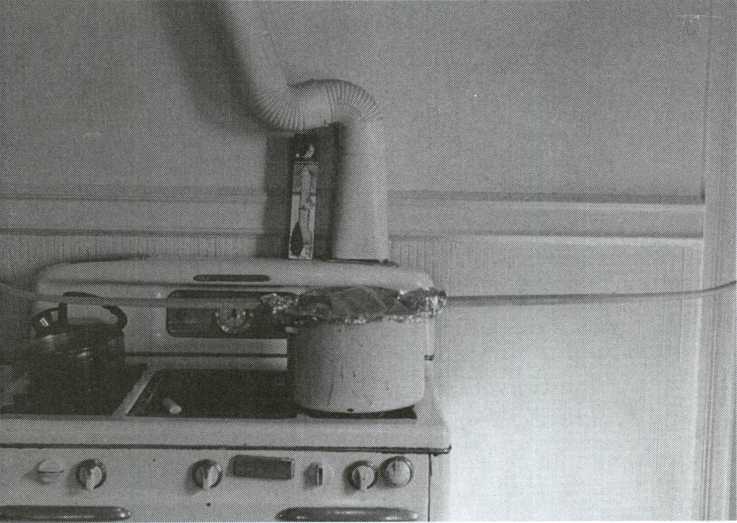

The most simple set-up for steaming is to place a pan or pot on a stove or burner. Put water in the pan or pot. Position the wood over the pan or pot. Cover the top of the pan or pot with aluminum foil, keeping the wood under the foil.

The aluminum foil does not have to be air-tight. A certain amount of steam can leak out with no problem.

Keep an eye on the water level. A lot of water can steam away in an hour. If you have to add water to the pot, heat it first in a separate pot. This will keep your steaming set-up from cooling off. Use the same trick when boiling the wood.

If you let all the water boil out of your pot, you may wind up with charcoal instead of a bow.

When steaming wood, the water in the pot does not have to boil hard. It only has to be hot enough to steam. This is usually going to require that the water be boiling only slightly.

Steaming on a stove by covering the bow with foil.

Tim Baker's method of using stovepipe fixtures to steam an entire bow.

I use a pan about 12 inches long, six inches wide, and two inches deep. This is big enough to let me do any type of steaming 1 please. It may be the position of your stove in the kitchen prevents you from steaming wood. If so, spend a few dollars on a single-burner hot plate. It will make water hot enough to steam copiously.

Tim Baker sometimes likes to steam an entire limb. To do this, he constructed a steaming rig out of stove pipe. The stove pipe goes into a pipe wall fitting, the same sort of fixture builders use where a stove pipe enters a wall. The wide

Two methods of boiling wood outdoors over a fire; a large pot suspended by a tripod for recurving tips, and a long, open trough to boil a limb or even an entire bow.

Fitting covers the steaming pot. The stove pipe sticks into the room, resting on the back of a chair. A towel closes off the open end of the pipe, from which the bow protrudes.

A1 Herrin describes capping a long piece of pipe, filling the pipe with water, putting the capped end of the pipe in a fire, and boiling an entire bow or limb. Jim Hamm says it is safer to place the wood in cold water and bring them to boiling temperature together. Cold wood may crack if plunged into already boiling water, he says.

If your steaming pot or pan is shallow, take care that flame from a fire or gas range does not lick up the sides and scorch the wood.

Boiling also can be used when splicing billets. If the handle splices to not fit together well, boil them for 30 minutes. Pull them out of the water and clamp them together. The softened wood will mash together for a much tighter fit. After the wood dries thoroughly, disassemble the billets, then use the normal gluing and clamping procedure.

When bending yew or Osage, the wet wood can usually be removed from the press as soon as the wood cools with good results.

With other woods — including the white woods such as elm, hickory, ash and birch — it is safer to leave the wood on the press until it is completely dry. Removing these woods from the press when wet may allow the wood to resume its original shape.

DRY HEAT

In addition to boiling and steaming, bending can be done with dry heat. Bending wood with dry heat requires precautions. If the wood gets too hot, it will scorch or ignite. Dry heat can also remove considerable moisture from the wood. Which could make the bow break. This danger does not exist with steaming and boiling.

Bending wood significant amounts with dry heat takes a careful approach, like that described by Hamm in Bows and Arrows of the Native Americans. Hamm uses an outdoor propane grill whose temperature can be carefully monitored, and sets the grill on low or medium heat. He suggests this procedure be used only with bows that will be backed, because of the danger of the wood losing moisture. Hamm says green or half-green wood bends more easily and with less cracking than drier wood — regardless if steam or dry heat is used.

Bending small distances with dry heat can be accomplished if the heat source is right. I once had a 1,500-watt space heater that would make wood almost too hot to handle. Wood at this temperature could be bent about as much as 15 degrees off a straight line. Eventually, this heater broke. And I have not yet been able to find another like it that would get wood as hot.

For the first-timer best results can be expected by boiling or steaming the wood.

For the primitive technician interested in aboriginal methods, there is the hot rock method. A large rock can be heated (though not red-hot) in a fire, then removed from the blaze. Hold the limb against the rock and apply pressure. The warmer the wood gets, the easier it will bend. The wood is then held in place until the rock begins to cool.

Another method was described by Steve Allely in his chapter on Western Indian Bows in Volume I. Wet moss is placed on the section of the bow to be bent. A red-hot rock is placed on the moss, creating steam. After a few minutes of steaming, the limb can be bent by hand or tied to a form.

Even if a bowyer's career begins with perfect staves or lumber for bows, eventually he'll grow adventurous and attempt "character" bows, or recurves, or setback bows. This is when wood-bending techniques show their value.

World History

World History