During the early years of manufacturing in the United States, water wheels furnished most of the motive power. Plentiful steadily moving rivers and streams ensured the availability of this dependable source of power, and readily available water power was further enhanced by technological improvements in water wheels.

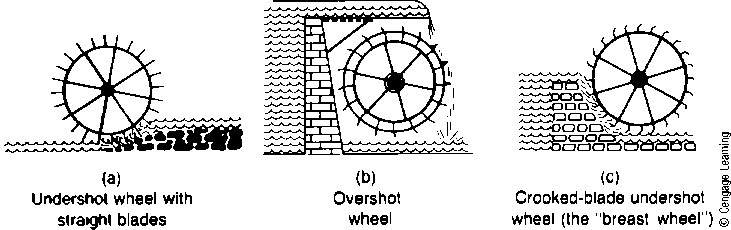

A water wheel is always placed in a vertical position on a horizontal shaft and is moved at a comparatively low speed by direct action of the water. Wheels are classified by the way water is applied to turn them (see Figure 10.1). The undershot wheel, which was used in colonial times and for a while thereafter in frontier areas, was placed in the stream so that its blades were moved by the water passing underneath it. Although easy to install, the undershot wheel was inefficient, transmitting no more than 40 percent of the power applied to it. The overshot wheel was moved by water running from a flume across the top of the wheel into buckets covering its surface; the weight of the water in the buckets moved the wheel in the direction of the stream flow. The overshot wheel was more efficient, easy to install, and satisfactory wherever there was a good head of water, but the power it developed was not great enough for heavy industrial purposes. Consequently, the large manufacturing concerns almost invariably used the breast wheel. This type, too, was equipped with buckets, but the water struck the wheel short of its axle so that it rotated in an upstream direction; both the impulse of the water and its weight in the buckets enabled the wheel to utilize up to 75 percent of the applied power. Installed in multiples, the breast wheel developed sufficient horsepower to serve the largest early nineteenth-century industrial firms. The machinery of the Merrimack Manufacturing Company, for example, was run by eight breast wheels, each 30 feet in diameter with buckets 12 feet long.

The slow-moving and cumbersome water wheels could develop several thousand horsepower, but they had marked disadvantages. Power from a wheel was transmitted by wooden shafts and cogwheels and was limited by the strength of the entire mechanism. Furthermore, industrial location was restricted to stream sites, and the problem of finding sites, especially in industrialized areas, became a serious one. The first difficulty was partially overcome by making wheels and transmission parts of metal, the second by the improved engineering of dams and canals. The water turbine, which revolved on a vertical shaft, was much more efficient than a wheel and by the 1850s was adding rapidly to the power potential of the country.

Finally came steam power, although its introduction into U. S. manufacturing was slow for several reasons. In the beginning, the steam engine was extremely costly to operate. Breakdowns were frequent, and expert repair technicians were rare. In transportation, the

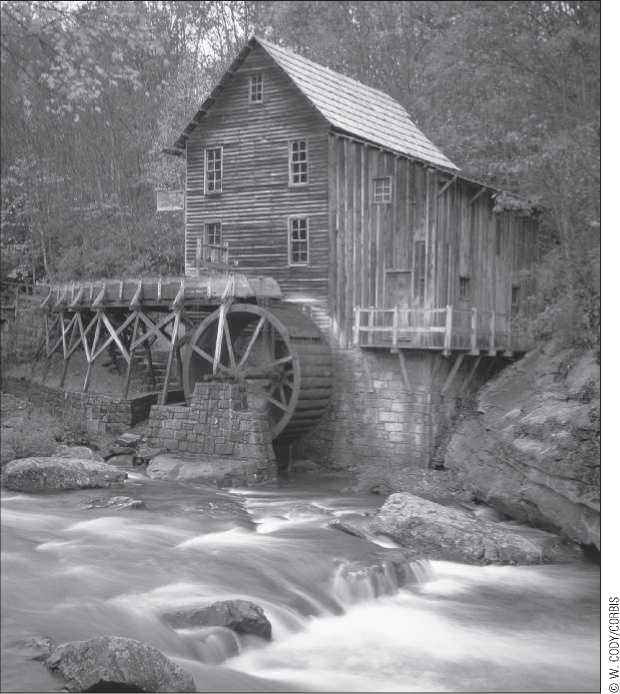

FIGURE 10.1

Water Wheel Designs

The three main engineering designs of water wheels that powered early textile and woodworking machinery are displayed here.

Steam engine could pull such heavy loads at such increased speeds that these disadvantages were more than offset, but in industry, water power remained cheaper than steam power for a long time. It has been estimated that, in 1812, only 11 engines of the high-pressure type developed by Oliver Evans were in use in this country (Clark 1916, 409).

During the next two decades, steam engines became more common in the South and West, but most of them were used in ironworks and glass factories that required fuel for other purposes or in mills that could not conveniently be located near water. Around 1840, manufacturers in New England and the Middle Atlantic states estimated the annual cost per horsepower of steam to be five or six times that of water. Within the next 20 years, improvements in metalworking technology lowered the cost of steam engines and improved both their efficiency and reliability. By the 1850s, steam engines were replacing water wheels in the heat-using industries and wherever stream flows were highly variable, as they were along the Ohio River. In New England, steam engines were being installed to power textile mills because of the serious lack of adequate power sites. As of 1860, water was still the chief source of power, but the years of the water wheel were clearly numbered.

Paralleling the rise of steam power, with a lag, was coal, which eventually became a major new source of energy. Because wood and, hence, charcoal were so cheap in the

This fairly typical overshot water wheel was one used in the 20,000 sawmills and 14,000 flour mills reported in the 1860 national census.

United States, however, the increase in coal use was slowed in comparison with its rapid adoption in England. Coal, like water, had a major impact on the location of manufacturing. With adequate transportation facilities, coal power increasingly allowed factories to be built in urban centers, and after 1830, coal-powered factories increasingly became a feature of the rise of manufacturing in the United States.

World History

World History